| Nominal size | Expanded ID | Recovered ID | Recovered Wall thickness |

|---|---|---|---|

| AWG-34 | 0.51 | 0.20 | 0.05 |

| AWG-33 | 0.64 | 0.25 | 0.05 |

| AWG-32 | 0.76 | 0.30 | 0.05 |

| AWG-30 | 0.86 | 0.38 | 0.05 |

| AWG-28 | 0.97 | 0.46 | 0.05 |

| AWG-26 | 1.17 | 0.56 | 0.05 |

| AWG-24 | 1.27 | 0.69 | 0.05 |

| AWG-22 | 1.40 | 0.81 | 0.05 |

| AWG-20 | 1.52 | 0.99 | 0.05 |

| AWG-18 | 1.93 | 1.24 | 0.05 |

| AWG-16 | 2.36 | 1.55 | 0.05 |

| AWG-14 | 3.05 | 1.83 | 0.05 |

| AWG-12 | 3.81 | 2.26 | 0.05 |

| AWG-10 | 4.85 | 2.84 | 0.05 |

| AWG-8 | 6.10 | 3.58 | 0.06 |

| Nominal size | ID | Wall thickness |

|---|---|---|

| AWG-44 | 0.05 | 0.05 |

| AWG-42 | 0.06 | 0.05 |

| AWG-40 | 0.08 | 0.05 |

| AWG-38 | 0.10 | 0.05 |

| AWG-36 | 0.13 | 0.05 |

| AWG-34 | 0.15 | 0.08 |

| AWG-32 | 0.20 | 0.08 |

| AWG-30 | 0.25 | 0.08 |

| AWG-28 | 0.33 | 0.08 |

| AWG-26 | 0.41 | 0.08 |

| AWG-24 | 0.51 | 0.05 |

| AWG-22 | 0.64 | 0.05 |

| AWG-20 | 0.81 | 0.05 |

| AWG-18 | 1.02 | 0.04 |

| AWG-16 | 1.65 | 0.04 |

| AWG-14 | 1.85 | 0.04 |

| AWG-12 | 2.13 | 0.04 |

| AWG-10 | 2.49 | 0.05 |

| AWG-8 | 2.79 | 0.05 |

| AWG-6 | 4.11 | 0.06 |

| AWG-4 | 5.18 | 0.09 |

| AWG-2 | 6.55 | 0.10 |

| AWG-0 | 8.26 | 0.13 |

IND is the fiber porosity level that indicates the expansion of ePTFE. IND 1 μ to 200 μ are available at ZEUS.

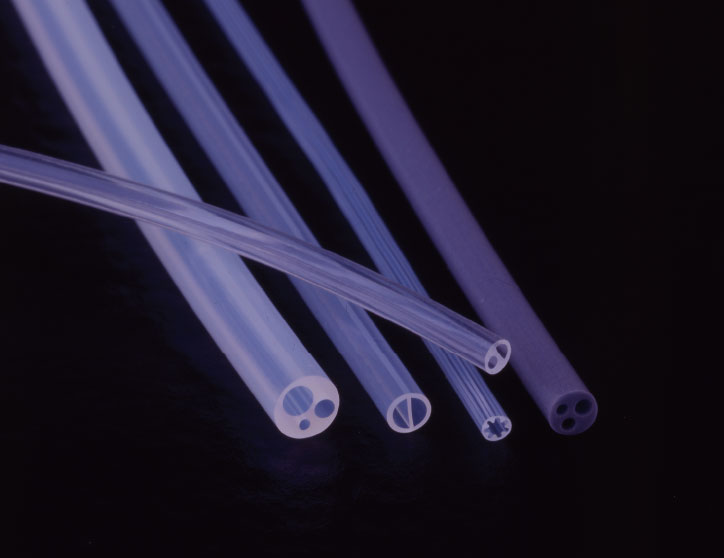

PTFE Sub-Lite-Wall® StreamLiner™ series is a line of ultra-thin products that were developed from revolutionary and in the most advanced class of technology.

They use more than 50 years of ZUES’s experiences in extruded polymer tubing.

StreamLiner™ is the thinnest extruded tubing among other Sub-Lite-Wall® line-ups with the thickness of 0.127mm (0.005’’) or less. StreamLiner™ enables engineers to design advanced catheter to improve patients’ cares and clinical outcome.

● StreamLiner™XT achieved for the first time in the StreamLiner™ series the wall thickness of 0.01905mm (0.00075’’).

● StreamLiner™VT is the same line of product with the wall thickness of 0.025mm(0.001’’).

With ZEUS LoPro™ technology and the thinnest wall thickness in the industry, Sub-Lite-Wall® StreamLiner™ series enable device engineers to increase catheter lumen space and effectively lower the overall profile of the device. In addition, as a free extrusion, it also affords a stronger and more robust catheter liner with reduced deployment force compared to liners made using a dip-coated process.