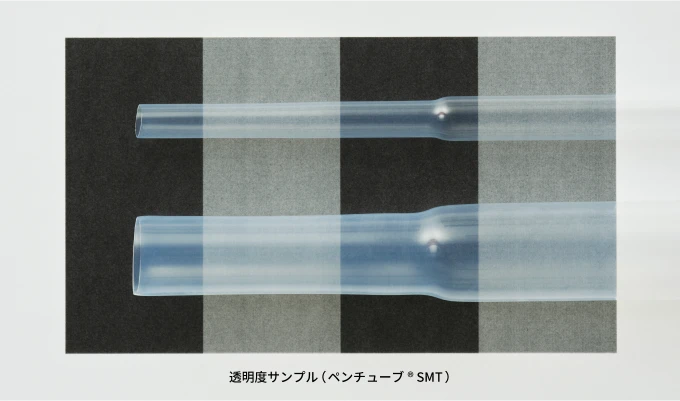

SMT is a versatile, standard heat shrink tubing that can be processed at low temperatures and offers excellent economic efficiency and versatility.

Main features of Penntube® SMT

Standard heat shrink tubing that can be easily processed

Ideal for covering materials of simple shapes

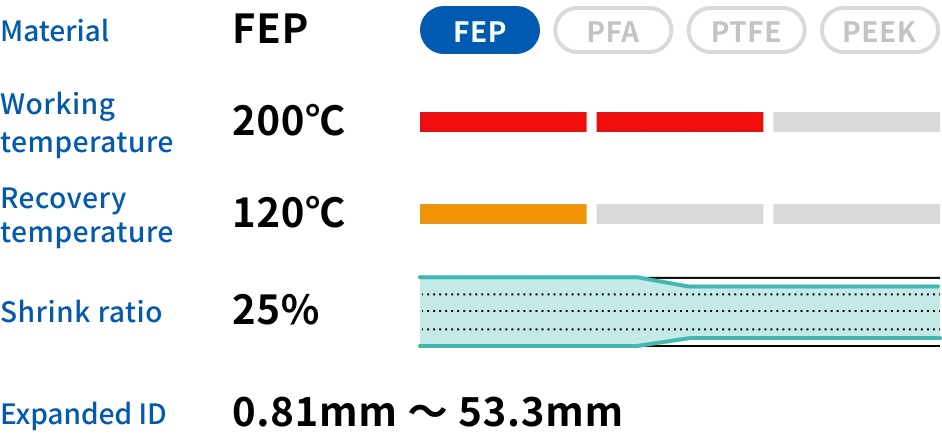

With a shrink ratio of 25%, it is ideal for covering materials of simple shapes. This product is featured by its easy processing and versatility.

Capable of welding

SMT is made of FEP that enables welding. It has excellent processability and chemical resistance, and offers high performance next to PTFE.

Recovery at low temperatures

Although its heat resistance is inferior to other materials, this product’s recovery temperature is low, making it easy to use in situations where temperature control is required.

Main features of Fluoropolymer

-

Strong to Heat

Heat-resistant and flame-retardant

-

Change Resistant

Chemical-resistant, weather-resistant, staining-resistant

-

Electrical Resistant

Resistant to electricity Insulation properties

-

Smooth

Lubricity Low friction (smoothness), non-adhesive

Main Purposes

- Medical equipment

- Scientific equipment

- Testing equipment

- Analytical equipment

- Measuring equipment

- Semiconductor manufacturing equipment Sensor protection

- Piping protection

Dimensions & Technical information

Video

Product

Flexible tubing

The inner diameter remains almost unchanged even when tube is bent, excellent in flexible piping, and the tube can be expanded and contracted. It can be used to the inside of equipment in small spaces. It is also used as a piping material for fluid transfer in various fields.

-

Pennchem® CT

Pennchem®CT

This tube is easy to bent with corrugated (annual) part.

-

Pennchem® TX

Pennchem®TX

This tube has a convoluted part that does not allow liquid to stay.

Heat shrink tubing

Tubing that shrinks when heated, used for coating parts, etc. It can provide heat resistance, insulation, non-adhesiveness, and slipperiness to the covering objects.

Various shrink ratios and sizes are available for a variety of applications.

-

Penntube® SMT

Penntube® SMT

This product is standard heat shrink tubing that is easy to process at low temperatures and meets various applications specifications.

-

Penntube® SST

Penntube® SST

This tube has a high shrink ratio that meets the specifications for complex shapes.

-

Penntube® PFA

Penntube® PFA

This tube has excellent slipperiness even in high-temperature environments and strong shape retention.

-

Penntube® TFE

Penntube® TFE

It has good slipperiness and retains its shape even at 327°C.

-

Penntube® TFE4X

Penntube® TFE4X

It has the largest shrink ratio up to 1 to 4.

-

Penntube® WTF

Penntube® WTF

This tube is a dual type tube that has high adhesion and contact properties.

-

Finetube SLW®-HST

PenntubeSLW®-HST

Heat shrink tubing that can meet precise customization requests

-

PEEK shrink®

PEEK shrink®

Heat shrink tubing with high abrasion and radiation resistance. This tube is ideal for protecting inside materials in high temperature environments.

Finetube

Super slim tubing that is used for medical and industrial devices. It is also called straight tubing or spaghetti tubing.

-

Finetube ePTFE

Finetube ePTFE

This tube is porous, flexible, and soft. It has a low dielectric constant, strong, and has excellent biocompatibility.

-

Finetube SLW® XT&VT

Finetube SLW® XT&VT

This tube enables engineers to design advanced catheter to improve patients’ cares and clinical outcome.

-

Finetube SLW®-SPA

Finetube SLW®-SPA

This product is all custom made. Ultra-thin spaghetti tubing.

-

Finetube MTL®

Finetube MTL®

MTL is all custom-ordered. It can be processed in various forms. Provide your form request for your application when ordering.

-

Finetube SPA-TFE

Finetube SPA-TFE

This product is a versatile spaghetti tube.

-

PEEK™

PEEK™

PEEK is used as a material alternative to stainless steel in cutting-edge industries such as aerospace, medical equipment, and analyzers.