Its small bending radius allow for highly flexible piping.

Main features of Pennchem® CT

Tubes with excellent bend radius that enables flexible piping

Processing of corrugated part

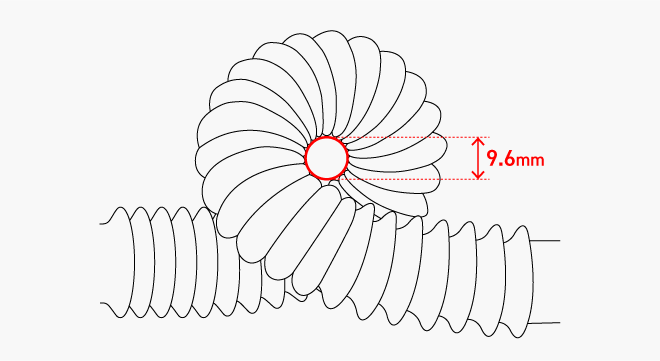

Corrugated parts can be contracted up to around 50% or elongated to around 140%. The bend radius is small (about 1/4 of its inside diameter) with almost no change in inside diameter when bent. The piping flexibility is more excellent than the convoluted tubing.

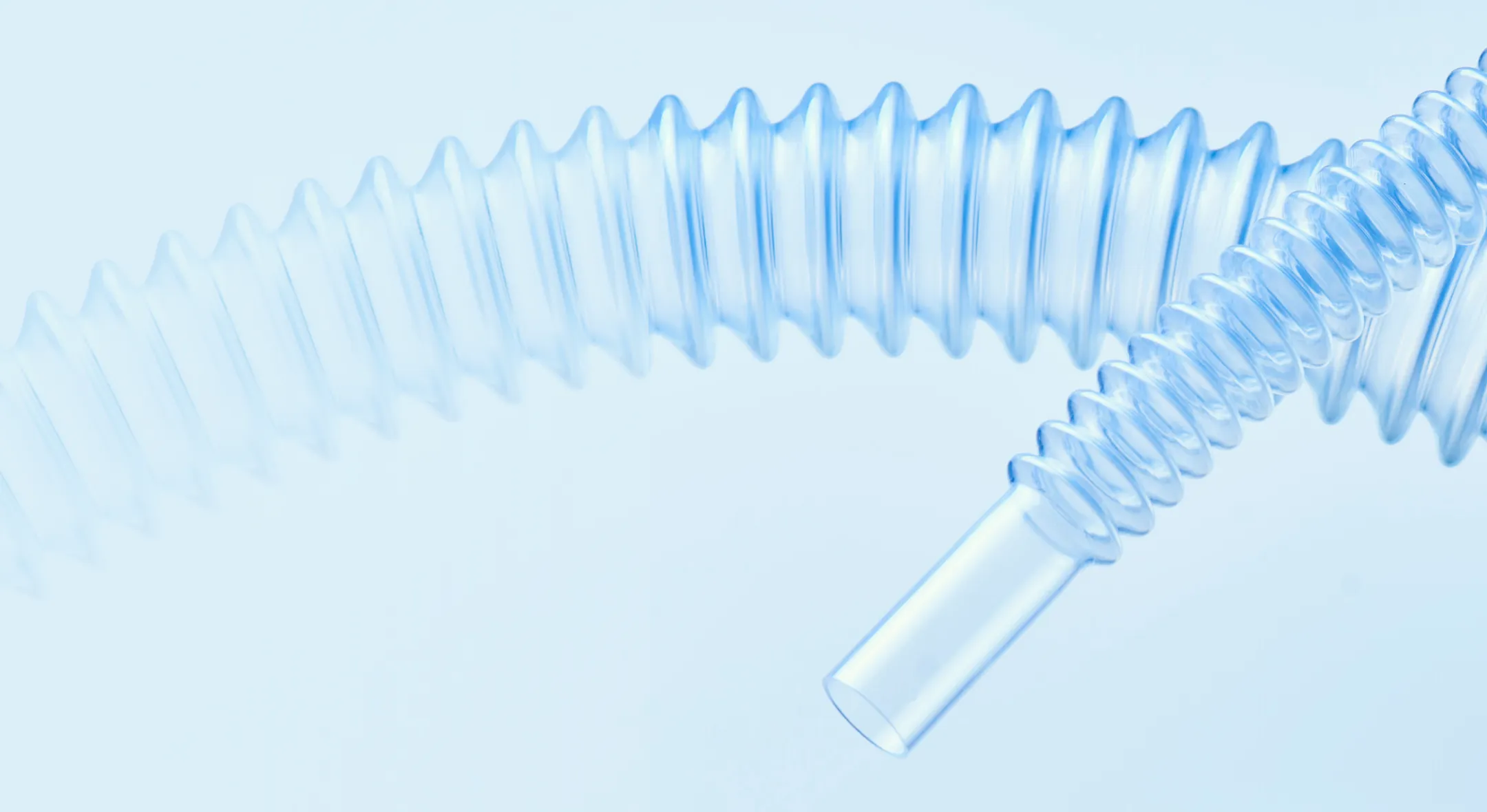

Fluids inside are easily visible

Transparency is high and fluids inside are easily visible.

Material : Fluoropolymer PFA

Working temperature : 150℃

Main features of Fluoropolymer

-

Strong to Heat

Heat-resistant and flame-retardant

-

Change Resistant

Chemical-resistant, weather-resistant, staining-resistant

-

Electrical Resistant

Resistant to electricity Insulation properties

-

Smooth

Lubricity Low friction (smoothness), non-adhesive

Main Purposes

- Semiconductor manufacturing equipment Factory piping

- Cleaning equipment

- Scientific equipment

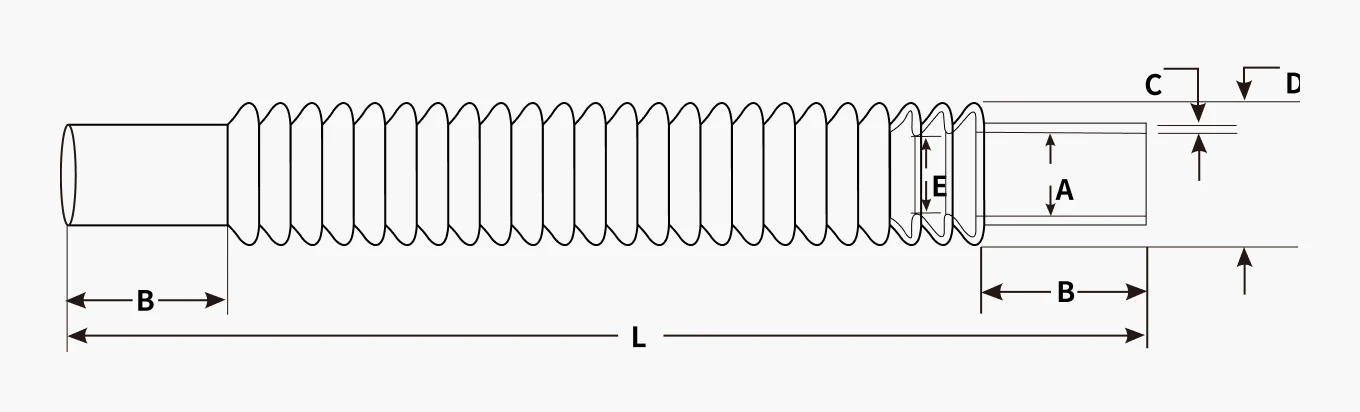

Dimensions and specifications

| Size | Straight part | Corrugated part | Min. bending radius |

Bursting press. (MPa) |

|||

|---|---|---|---|---|---|---|---|

| Inner rad. | Thick | Length | Min. rad. | Max. rad. | |||

| A | C | B | E | D | R | ||

| 1/4 | 6.0 | 0.41 | 19 | 5.5 | 9.4 | 1.6 | 1.24 |

| 3/8 | 9.2 | 0.55 | 25 | 8.5 | 14.0 | 2.4 | 1.18 |

| 1/2 | 12.1 | 0.68 | 25 | 11.0 | 18.2 | 3.2 | 0.96 |

| 5/8 | 15.5 | 0.73 | 25 | 14.5 | 22.7 | 4.0 | 1.00 |

| 3/4 | 18.7 | 0.78 | 38 | 17.4 | 22.7 | 4.0 | 1.00 |

| 1 " | 24.8 | 0.93 | 50 | 23.0 | 34.5 | 6.4 | 0.84 |

| 1-1/4 | 31.2 | 0.93 | 50 | 29.3 | 41.4 | 7.9 | 0.67 |

| 1-1/2 | 37.4 | 0.97 | 50 | 35.2 | 48.8 | 9.6 | 0.57 |

| 2 " | 50.1 | 1.10 | 50 | 47.2 | 64.5 | 12.7 | 0.48 |

Standard Length (Overall L)

| ft | 1 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 | 7 | 8 | 10 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| m | 0.305 | 0.458 | 0.610 | 0.763 | 0.915 | 1.068 | 1.220 | 1.525 | 1.830 | 2.135 | 2.440 | 3.050 | 3.660 |

- Length units are indicated by feet.

- Maximum length is 12 feet.

- Corrugated length is subtracted the straight part

- The length may vary between the normal state and the state in supplying.

Half sized

| Size | Overall Length | Straight part | Corrugated part | Straight part | Sales units |

|---|---|---|---|---|---|

| 1/4 | 171 | 19 | 133 | 19 | 5 |

| 3/8,1/2,5/8 | 177 | 25 | 127 | 19 | 5 |

| 3/4 | 190 | 38 | 114 | 38 | 3 |

| 1 " | 200 | 50 | 100 | 50 | 3 |

| 1-1/4,1-1/2 | 200 | 50 | 100 | 50 | 2 |

| 2 " | 200 | 50 | 100 | 50 | 2 |

- Half-sized are also available.

- Parameters shown on table are indicating normal values.

Temperature and burst pressure drop

-

The graph above shows the relationship between burst pressure and temperature for Pennchem® CT and Pennchem® TX.

Example) What is the burst pressure of Pennchem® CT1/2" at 100°C?

0.96MPa×0.58=0.56MPa - The safety pressure is designed to be 1/3 to 1/5 of the burst pressure at normal working temperatures.

- When considering the use of Pennchem®CT and Pennchem®TX, please take into account the conditions of use, such as an impact, hazardous nature of fluid, and joint type.

- Please confirm the usability and safety of Pennchem®CT and Pennchem®TX by testing beforehand.

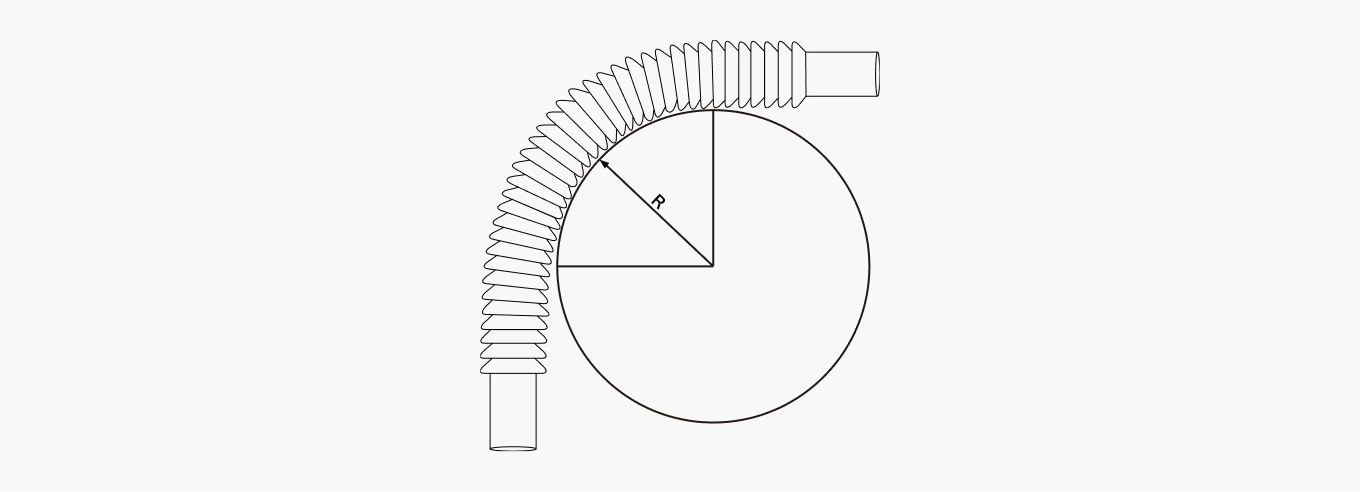

Minimum bending radius

| Size | 1/4 | 3/8 | 2/1 | 5/8 | 3/4 | 1 " | 1/4 | 1-1/2 | 2 " |

|---|---|---|---|---|---|---|---|---|---|

| CT | 1.6 | 2.4 | 3.2 | 4.0 | 4.8 | 6.4 | 7.9 | 9.6 | 12.7 |

| TX | 12.7 | 22.2 | 31.8 | 38.1 | 50.8 | 56.5 | 69.9 | 76.2 | 108.0 |

- Intertwine the tube and it does not make damage

- Calculating formula is D=Rx2.

- At the room-temp

- Don't bend tubes more than bending limit.

An image of the bending radius

PennchemCT 3/4”

R=4.8

*R=D/2

Main properties

Product

Flexible tubing

The inner diameter remains almost unchanged even when tube is bent, excellent in flexible piping, and the tube can be expanded and contracted. It can be used to the inside of equipment in small spaces. It is also used as a piping material for fluid transfer in various fields.

-

Pennchem® CT

Pennchem®CT

This tube is easy to bent with corrugated (annual) part.

-

Pennchem® TX

Pennchem®TX

This tube has a convoluted part that does not allow liquid to stay.

Heat shrink tubing

Tubing that shrinks when heated, used for coating parts, etc. It can provide heat resistance, insulation, non-adhesiveness, and slipperiness to the covering objects.

Various shrink ratios and sizes are available for a variety of applications.

-

Penntube® SMT

Penntube® SMT

This product is standard heat shrink tubing that is easy to process at low temperatures and meets various applications specifications.

-

Penntube® SST

Penntube® SST

This tube has a high shrink ratio that meets the specifications for complex shapes.

-

Penntube® PFA

Penntube® PFA

This tube has excellent slipperiness even in high-temperature environments and strong shape retention.

-

Penntube® TFE

Penntube® TFE

It has good slipperiness and retains its shape even at 327°C.

-

Penntube® TFE4X

Penntube® TFE4X

It has the largest shrink ratio up to 1 to 4.

-

Penntube® WTF

Penntube® WTF

This tube is a dual type tube that has high adhesion and contact properties.

-

Finetube SLW®-HST

PenntubeSLW®-HST

Heat shrink tubing that can meet precise customization requests

-

PEEK shrink®

PEEK shrink®

Heat shrink tubing with high abrasion and radiation resistance. This tube is ideal for protecting inside materials in high temperature environments.

Finetube

Super slim tubing that is used for medical and industrial devices. It is also called straight tubing or spaghetti tubing.

-

Finetube ePTFE

Finetube ePTFE

This tube is porous, flexible, and soft. It has a low dielectric constant, strong, and has excellent biocompatibility.

-

Finetube SLW® XT&VT

Finetube SLW® XT&VT

This tube enables engineers to design advanced catheter to improve patients’ cares and clinical outcome.

-

Finetube SLW®-SPA

Finetube SLW®-SPA

This product is all custom made. Ultra-thin spaghetti tubing.

-

Finetube MTL®

Finetube MTL®

MTL is all custom-ordered. It can be processed in various forms. Provide your form request for your application when ordering.

-

Finetube SPA-TFE

Finetube SPA-TFE

This product is a versatile spaghetti tube.

-

PEEK™

PEEK™

PEEK is used as a material alternative to stainless steel in cutting-edge industries such as aerospace, medical equipment, and analyzers.